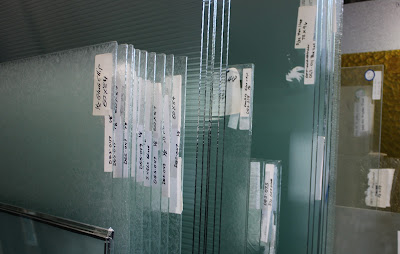

In the design studio area, there are hundreds of samples of glass in various textures that Dependable Glass works can fabricate upon request. In the back room, the walls are covered with framed mirrors in various sizes and shapes.

Click on the images to make them larger.

The showroom is impressive, but it represents only a small percentage of what goes on inside the fabrication plant at Dependable Glass Works where they cut, laminate, insulate and temper glass for both residential and architectural customers.

Round glass table tops

There’s a display in the front showroom of circular glass that can be used for table tops. Part of the fabrication process at Dependable Glass is cutting, polishing and shaping the edges.

In the plant there is a very large computerized cutting table that allows Dependable to cut shapes. Down the street in their second location at E. Gibson and Lee Lane they have a “water-jet” cutting table. The water-jet cutting table can cut glass thicknesses of up to 10” in any shape. They even produce glass cut in the shape of the state of Louisiana.

Big Louisiana

Small Louisiana

“The heartbeat of the operation is the beveler” Norman Foxworth, founder of the company, stated. It is the machine that produces beveled edges, from a choice of several styles. Beveled glass edges are what makes a lot of glass products especially attractive. One of the employees who specialize in the beveling process has been with the company for 45 years.

Getting the edges smooth and clear calls for not only the right equipment but for the workers to use extreme skill and precision. Sometimes Dependable will hand polish the glass instead of machine polish if required.

Business Began 52 Years Ago

Norman Foxworth grew up in Covington and graduated from Covington High School in the class of 1962. He’s worked in the glass industry his entire life. He started out working for his family in the auto and plate glass business and then founded Dependable Glass Works in 1967. Since then Norman has become widely known as an innovator in the glass fabrication business.

These company photos were taken in 1979, forty years ago

(Photos by Ron Barthet)

Norman Foxworth once served as president of the chamber of commerce

Dependable Glass Works in 2019

Norman Foxworth

He purchased beveling machines, polishing machines, and cutting machines. In 1998 he introduced Safety-Plus impact resistant glass to the area. They also laminate glass which ranges from hurricane resistant to bullet resistant to large missile testing. In 2008 he started producing “insulated glass”. He took a part of his laminating facility and created a fabrication line for insulated glass windows.

In 2018 Dependable Glass Works opened a tempering department in North Covington. This requires a special building because of the “tempering oven” required to temper glass. This allowed Dependable to broaden its fabricating capacity with in-house services. They can temper small size glass 6” x 6” inches up to 120” x 60”. Tempered glass is used in flooring, handrails and shower insulations. The furnace heats the glass to a set temperature which strengthens the glass to minimize breakage.

The majority of what they fabricate at Dependable Glass Works is customized for the resident or architect/designer. Whether it be size, color or texture, art glass, flooring or counter tops, Dependable Glass Works has become the largest stocking dealer of textured glass in Southeast Louisiana and imports containers of specialty glass from Europe and Asia.

Often architects and designer contact Dependable when they are trying to create something special, such as when they are called upon to mix and match textures and colors, laminate objects in glass such as marbles, Mardi Gras doubloons, or old black and white negatives and interlayers designs.

Some of his orders call for fairly large pieces of glass, so much so that he had to install a heavy duty crane in his facility.

Dependable Glass Works has some high profile clients including Tiger Woods, Britney Spears – Children Hospital project, and the Bill Clinton Library. The company has placed its work in the Superdome in New Orleans, outside the Superdome in the Saints fan ticket holder display, and in retail stores, casinos, hotels and office buildings across the country.

Whenever the need arises, Dependable Glass Works fabricates glass and mirrors for custom-installations, even antique mirror glass and antique reproduction glass, which looks like glass from the 19th century but has the stability of glass from the 21st century.

The 1960’s glass company has grown into a multitude of special services, employing over 35 people. They open their doors sometimes at 5:00 am in the morning and work til about 3:30 pm in the fabrication department. The staff is cross trained so that they can work in multiple departments within the company.

Dependable Glass Works trucks deliver glass all over the Southeastern United States. The Covington-based company is meeting the needs of a wide variety of personal, architectural and commercial applications for the 21st century. And yet, to onlookers visiting downtown Covington, it is still a quaint Columbia Street retail shop as well.

The 1960’s glass company has grown into a multitude of special services, employing over 35 people. They open their doors sometimes at 5:00 am in the morning and work til about 3:30 pm in the fabrication department. The staff is cross trained so that they can work in multiple departments within the company.

Dependable Glass Works trucks deliver glass all over the Southeastern United States. The Covington-based company is meeting the needs of a wide variety of personal, architectural and commercial applications for the 21st century. And yet, to onlookers visiting downtown Covington, it is still a quaint Columbia Street retail shop as well.

Foxworth looks over some oval pieces about to be polished.

An array of textured glass waiting for orders

Here are some photographs of the neat things on display in the front showroom.

Hunk of glass, green

In the WGNO article, they say that while Dependable Glass now "supplies glass to the world," it started by offering glass for cars and homes. In the early days of the company, when Foxworth saw what other glass companies around the country were offering their customers, over and above the windshield repair business, Dependable began to expand upon its services.

"Dependable Glass is now one of the leading glass companies in the country. It supplies glass for locals, the military, and NASA. The company has customers as far away as Japan. Contractors around the world know that if they need some sort of specialty glass for a project, Dependable Glass is the place to get it," the WGNO report stated.

In a recent design challenge, Dependable Glass took part in the creation of a glass art sculpture at Utah State University. Here's the story:

Glass Sculpture Represents Life-Sustaining Water Droplets

Glass and water look similar, in many ways, and because of that, the Utah State University and the Utah Division of Arts & Museums chose glass to represent life-sustaining water in its 23 foot-high art sculpture entitled "Surface Tension," recently installed in the lobby of its College of Life Sciences building.

The artwork consists of 534 unique glass "drops," clinging to a 17 foot wide steel structure that dominates the interior landscape.

The “drops,” which vary in size from 12 to 42 inches, were individually cast and adhered to laminated glass bases, illuminated from the sides by an internal LED light. Dependable Glass Works of Covington, Louisiana, was part of a team of experts to work on the challenging project.

According to Amy Landesberg of Amy Landesberg Art & Design, Inc., the piece of art deploys cast glass to “evoke the materiality of water... water, because there is no biological system without it, and it is therefore crucial to the study of life sciences.”

“The glass mimics water in three ways: structure – (the water drop sizes and shapes were analyzed and used as the basis for casting); effect – (glass chill marks and light refraction create watery light);and image – (images of life developed with the help of the college faculty can be discerned through careful examination of some of the drops).

Creating “Surface Tension” required a team of professionals from across the nation, including Amy Landesberg Art & Design, Inc., ARW Engineers, Uzun + Case, Spectrum Engineers, VCBO Architecture, Ducworks, Inc., Shatone, LLC., Cache Valley Electric, FGD Glass Solutions, Blenko Glass, as well as Dependable Glass Works.

Each one of the 534 glass drops is unique, and to accomplish this, the solid glass drops were made in three steps which called upon the creativity, the “awe-inspiring” expertise, and the problem-solving capability of every person taking part in the fabrication.

The first step involved casting the glass drops in eight graphite molds custom designed for them. After casting, each drop was then matched to its location on a full-size vinyl drawing of the drops pattern with an associated number code. This process took place at Blenko Glass in Milton, West Virginia.

The second step created a laminated glass substrate which would prevent glass breakage and securely mount the glass to backing steel. This required a laminated layer of safety glass, cut to match, which was adhered to each cast drop. This translucent layer also diffuses the back lighting.

The third step cut a specially-shaped piece of laminated glass and joined it to the simulated drops. The laminated glass drop shapes were cut on a water jet table at Dependable Glass Works in Covington. Then each laminated drop was in turn laminated to each cast drop. The lamination process used was the GLASSLAM System, said Norman Foxworth, President and Founder of Dependable Glass.

“Surface Tension” heightened the effect by internally lighting the art wall with two 19 foot-long LED lighting fixtures, one on each side. This electrical work was designed and specified by Spectrum Engineers, the building design team electrical engineer. The lighting effects can be dimmed as desired.

Glass plays well with light, and because of that architects have, for hundreds of years, called upon glass to add sparkle to their projects. Whether it be large works of art such as this, or windows, doors and floors, glass can not only take centerstage, but it can also accentuate the shape and design of other materials in ways that intrigue and enlighten. Building designers have always had a clear understanding of how glass can reflect on their work in innovative ways.

Artists and craftsmen, such as the ones who produced “Surface Tension,” showcase this creativity by using glass to brighten both workspaces or homeplaces. This artwork shines a spotlight on water, life and the evolutionary connection between the two, and glass made it possible to capture this essence and display it with beauty and meaning.

Dependable Glass Works works with architects, artists and designers around the nation to bring their ideas to light: shaping, texturing and fabricating glass products for a wide array of applications. The company, established in 1967, focuses on bringing an awareness of the versatility of glass: its strength, its beauty, and most of all, its ability to fascinate all those who look upon it.

Students Enjoy High Tech Tour Of Glass Company

Twenty students from Mandeville High School toured Dependable Glass Works in Covington recently, seeing a variety of high-tech glass fabrication machines and learning of the newest techniques in preparing glass for a multiude of modern-day uses.

Norman Foxworth, president and founder of the company, guided the tour, moving the group and its paraprofessional guides from one end of nationally-renowned glass company to the other a city block away. The “field trip” started in the display showroom, where numerous examples of the company’s workmanship were on view, from countertops and shower enclosures to pieces of art.

The kids were amazed at the versatility of the material, and they asked some interesting questions about glass’s history, uses, and industrial applications. “Glass comes in here by the truckloads,” Foxworth told the students. “We cut it to size and then add value to it. Some part of this process is on the artsy side, and we enjoy taking part in those challenging projects. If you went to the Bill Clinton Library in Little Rock, Arkansas, you would see glass that was fabricated right here in our shop.”

“Everybody has heard of Tiger Woods, well, we’ve done a lot of work for Tiger Woods,” Foxworth stated.

See also: